Rolling Mill Section

Production Process:

Key Responsibilities:

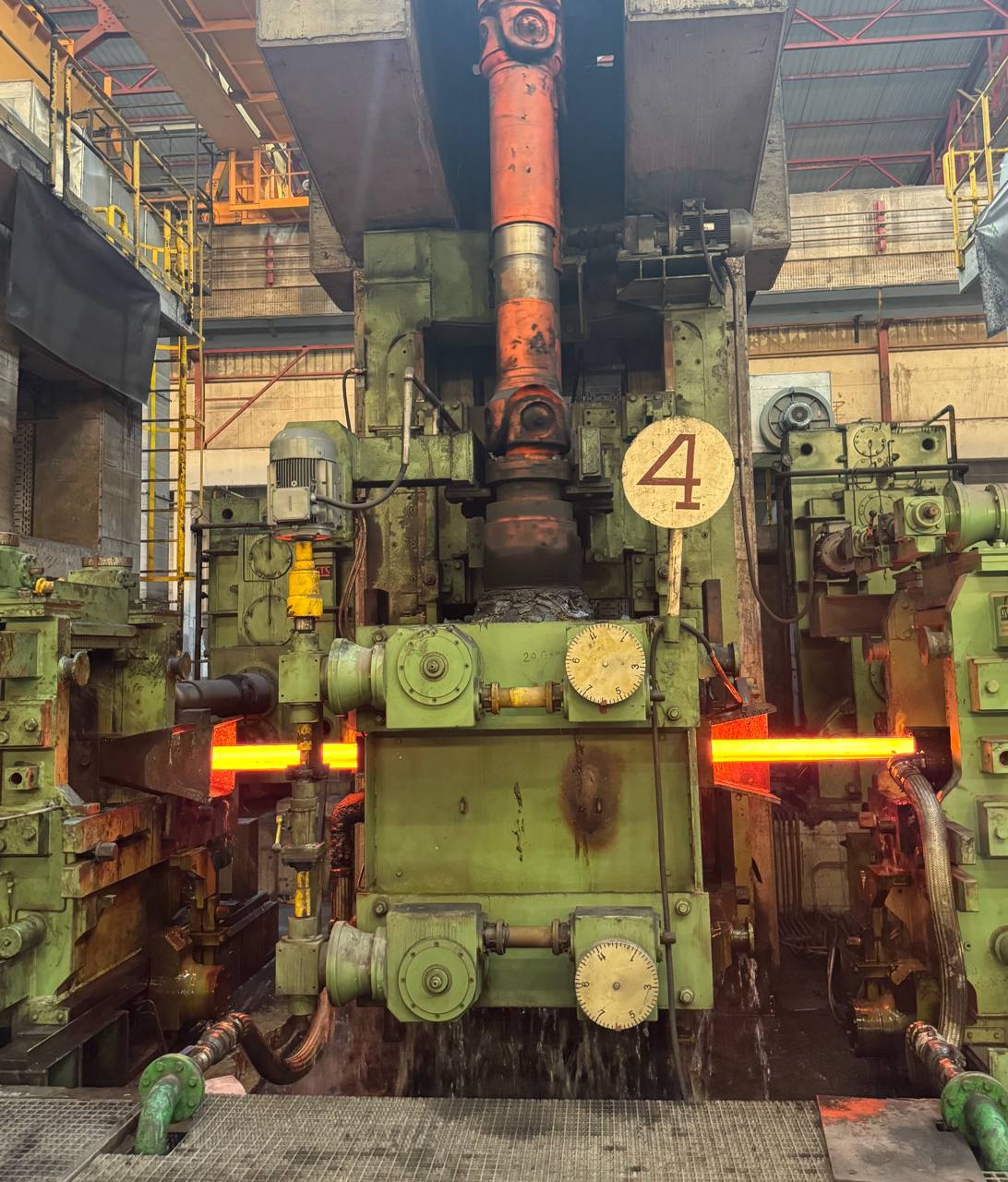

The Rolling Mill Section processes billets produced from continuous casting and transforms them into rebar of various sizes, adhering to international standards.

1.Heating the Billets:

- Square billets (150×150 mm) are heated to high temperatures to prepare them for the rolling process.

2.Rolling Process

-

Heated billets are passed through rolling equipment to shape them into rebar of different cross-sectional sizes based on usage.

Standard sizes produced: 10, 12, 16, 20, 25, 32 mm.

Custom sizes produced on request: 8, 14, 22, 28 mm.

3. Compliance with Standards:

All products are manufactured in accordance with international standards:

• American Standard ASTM

• British Standard BS

• Global Quality Standard ISO

Production Capacity:

- The rolling mill has a production capacity of 600,000 tons annually, reflecting operational efficiency and the ability to meet local and international market demands

The Rolling Mill Section represents the final stage of producing high-quality rebar, designed to meet the requirements of construction and infrastructure projects while strictly adhering to global standards.

Production Process:

- Scrap is melted in the Electric Arc Furnace using electrical energy, natural gas burners, and oxygen.

- Molten steel is processed in the Ladle Furnace to ensure product purity and achieve the required characteristics.

- The molten steel is transferred to the continuous casting machine to produce billets with a 150×150 mm square cross-section.

The steel section forms the core of the production operations at Iraqis Haded Company, where advanced technologies and equipment ensure high-quality products, while maintaining environmental and safety standards.